When it comes to printed materials that are going to be consumed orally, it’s important to focus on using FDA food approved safe materials. For example, when you have a pet before it puts anything into its mouth like a pet-related toy or product, you would research it, to make sure it’s safe and doesn’t contain anything harmful. The same goes for a bong.

Even though it’s just used for inhalation, it’s something that is going into your mouth and heat resistance plays a key role. Before lighting up marijuana in this thing, you need to do your research.

But Why Should You Print A 3D Bong?

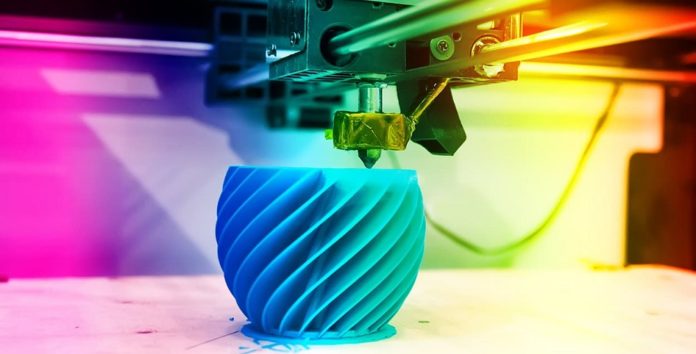

Let’s answer the simple question. Why print a bong? Aren’t there other purposes for a 3d printer? Well, let’s explore. There’s creating human and animal prosthetics, helping save lives by printing human organs and building houses. Most certainly there are! The bottom line is that 3d printing a bong is a cool option.

Here are the Reasons Why You Should 3D Print A Bong

To get rid of safety concerns and prevent the taste of the smoke to get unpleasant. You can also get super creative with 3d printing a bong and the bowl that’s made from ceramic or class. For this, you will need a paste extruder for clay and ceramic printing. There’s also the option to have the bowl printed by a professional service like Shapeways. This 3d printing company prints on glass and since it’s a small part, you can get creative on the bowl. If it’s a cheap part, there’s no need to 3d print it.

Options Of Material

So you can probably guess where this is headed, but let’s discuss material options. Materials such as ceramics, glass and for all parts excluding the bowl, mouthpiece, and FDA approved Nylon.

Moreover, there’s one big reason why PETG and PLA can be added to that list with the exception of the mouthpiece and bowl.

Then there’s Max CLR FDA-approved epoxy. Remember, this adhesive becomes applicable when you apply it on the inside of the 3d print. The design needs to fulfill this requirement. The best way to use Max CLR FDA-approved epoxy is when it’s poured.

To avoid pooling it, pouring it is the ideal way to apply it. Keep in mind that it might not stick the first time. Prepare to apply multiple layers to achieve the best results.

Better Taste

The title mentions prevent bad taste. The one thing you don’t want to do is alter the taste of cannabis. You want to extract the best taste possible from the bong.

The good news is the MAX CLR adhesive most likely contains fumes and the scent will transform into taste on a 3D printed bong, right? The answer is no. It’s only applicable if you don’t give the adhesive the right amount of cure time. After the curing time has elapsed, it shouldn’t have a smell.

However, the taste can be enhanced during the time it cures and possibly after. Just add a little vanilla extract into the adhesive before you apply it to your bong. This trick has been applied by professionals to cancel out the smell, while the resin sets and cures. This trick is also useful with paint. During the curing period, the vanilla extract will evaporate and create a pleasant scent.

Here’s how to do it and give you an idea as to how much you need. Mix just a little bit by using a tablespoon per quart of paint. Double-check that you’re not using a dark coloured product. The adhesive’s original colour is clear, so if you plan to add a dark coloured vanilla extract, it will end up adding colour to the adhesive.

How Can You Add Some Weight?

One of the best things about 3d printing a bong is that you decide how much materials you want to use. But don’t overdo it. For printing on a bong, it’s suggested to add a little weight to it, to avoid it from feeling like a cheap toy when it’s done curing. It depends on the design, but here are some quick tips to add weight to the base. Include dense materials such as washers, add some sand or Plaster Of Paris. Or use a little infill to boost its weight.

![How to Install and Watch Paramount Plus on Xbox? [Updated 2023] How to Install and Watch Paramount Plus on Xbox](https://dandelife.com/wp-content/uploads/2023/05/How-to-Install-and-Watch-Paramount-Plus-on-Xbox-100x70.png)