Spectroscopy is an invaluable device that can help experts and hobbyists extract essential information from light measurements. Spectroscopes measure the quantity of light sop up by a substance. To be more clear-cut, these devices give a non-destructive tactic of measuring the amount of light spread out through a taster or reproduced from it, including during photoluminescence. Experts invented the first spectroscopy in 1939. Nowadays, spectroscopes are helpful in production facilities, quality control management, forensics, medicine, environmental testing, and more sectors. They enable professionals to measure kinetics, minerals, paint, lights, and other entities.

Due to the spectroscopy’s high demand, the market has lots of options, and to get a high-quality product like Agilent UV VIS spectroscopy, due diligence is a must. Below are factors to consider in choosing spectroscopy.

Type of Spectroscopy Sensor

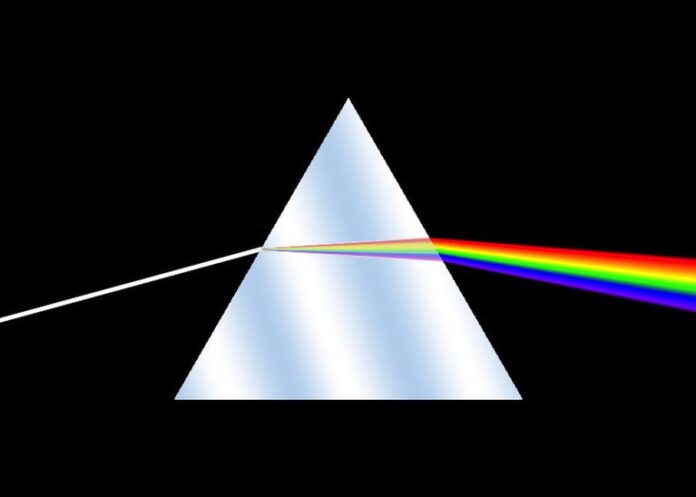

You will have to choose the kind of sensor you want to utilize in your spectroscopy. Many detectors are made with a photodiode array (PDA). For typical uses, you’ll be okay with a PDA. However, some units utilize a coupled detector (CCD). CCDs offer extremely low readout noise, but they are fabricated in such a manner that they take in UV light. A UV-VIS spectroscopy is an ideal choice for gauging around that absorption problem. For wavelengths of 160nm-1100nm, semiconductor sensors are a great selection. Their coverage includes visible light, shortwave light, and UV light. For wavelengths between 900nm and 1700nm, your perfect choice is an Indium Gallium Arsenide detectors InGaAs. However, the kinds of substances you are measuring are the most crucial element of consideration.

Calibration

There are two categories of calibrations for spectroscopes, namely path length, and light source calibrations. The brilliance of the light source lessens with use and should be calibrated once after 1-2 years. You can simply do this by consulting the parameters the manufacturer gives and calibrating the unit yourself without having an engineer work on it. The biggest problem with the newest spectroscopes is, pave length isn’t easy to calibrate. Because of varying levels of taster concentration, the electric motor is applied to change path length. However, path length disarticulation caused by machinery also affects fixed formulas and parameters. Depending on the number of samples and incidence, the concentration needs to be calibrated one time per 3-6 years. Selecting a concentration with a built-in path length will help you solve the calibration issue. Users can manually select the appropriate path length based on the sample concentration.

Requirements

Since spectroscopes can be applied in various environments, they come in many shapes and sizes. Hence, you should have your goals and the device’s detection limits. Depending on users’ specific research intents, they can select between equipment that senses different wavelengths, for instance, atomic absorption spectroscopes, fluorometers, visible light spectroscopes, nuclear magnetic resonance machines, mercury analyzers, and near-infrared units. There are also microspectroscopes to gauge infinitesimal samples, proper for thin-film measurements, reflectometry, and microcalorimetry. Besides wavelength limits, other factors decide the grouping of units. Units can also be sorted according to the light path applied. There are split beam, single beam, and dual-beam units.

With a range of spectroscopes in the industry, selecting the correct unit might be a taxing task. To get a first-class spectroscope such as Agilent UV VIS spectroscopy, you should be cautious. By using the above tips, you’ll be sure of the unit you end up buying.